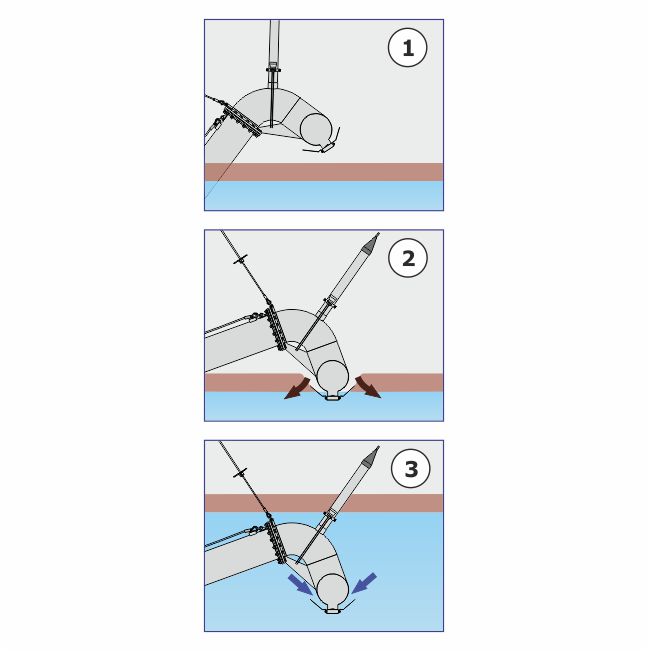

In contrast to secondary clarifiers in conventional treatment plants, the treated wastewater in SB-reactors cannot be discharged using an overflow channel due to process-specific reasons. As volume needs to be provided in the SB-reactor for new raw wastewater of the subsequent cycle, an extraction device for clear water is required, which follows the falling water level.

The decisive factor is here a discharge process which neither floating sludge nor activated sludge is captured. The decanting device also must offer a fail-safe operation, as it is one of the most important process components of a SBR wastewater treatment plant.

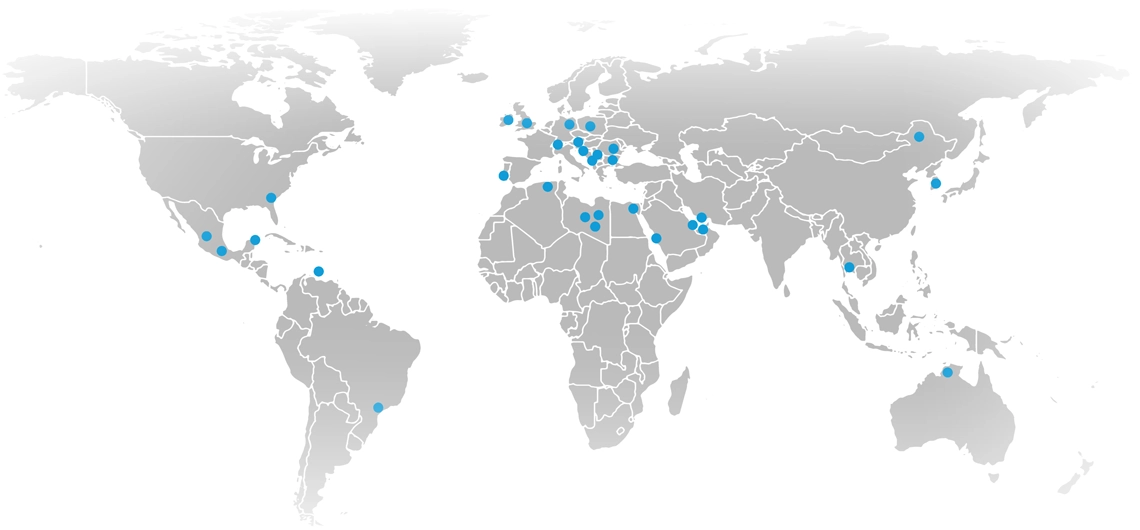

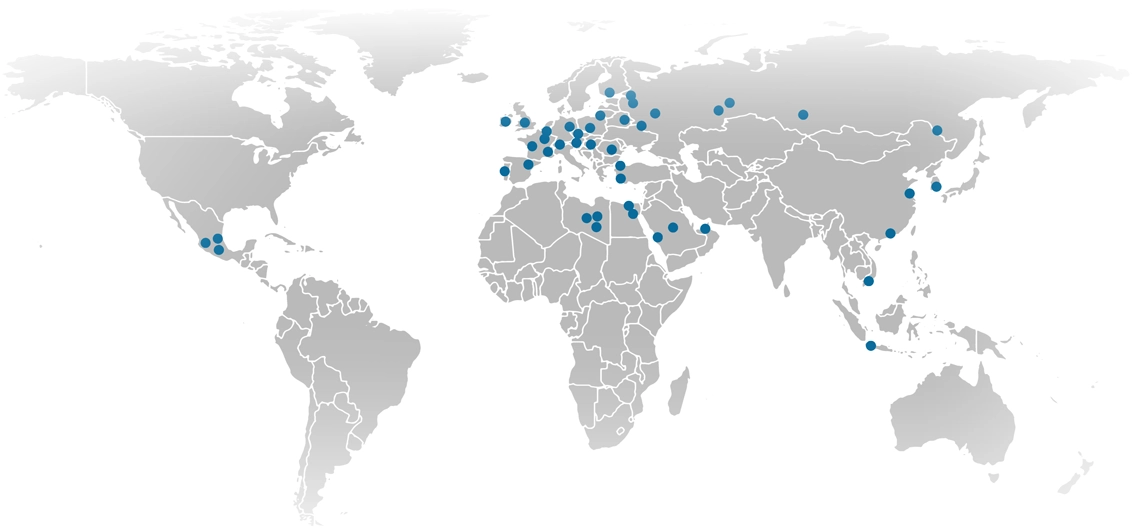

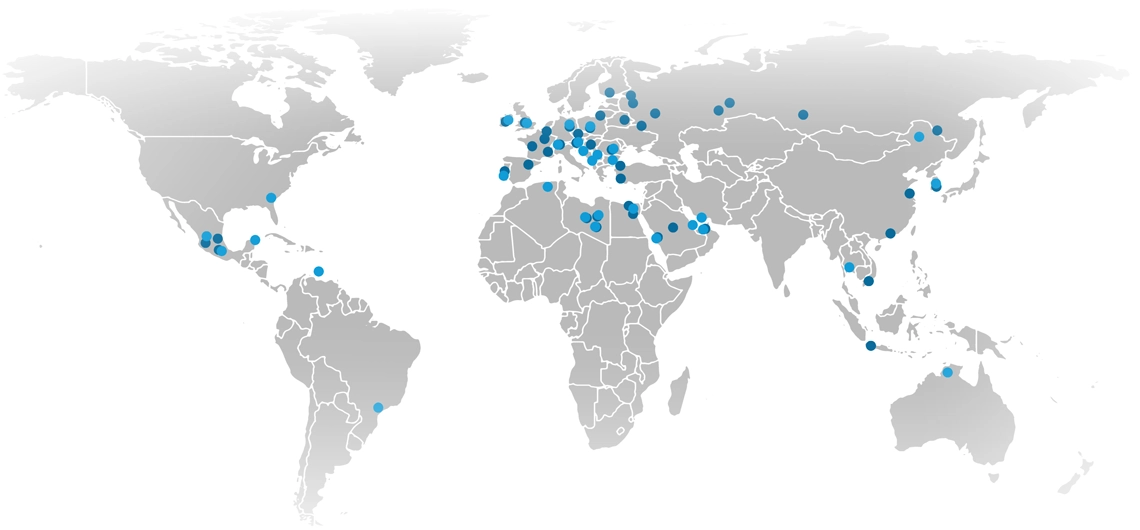

Our aim developing a clear water discharge device was mainly to create a system, which does not suffer from the known disadvantages of many existing systems. More than 400 installed BSK®-decanters around the world prove the successful product implementation. Following features have convinced and convince both planners and users:

Remarkable high discharge volume - already with small diameters

Two different discharge modes allow the end-user to adapt the water flow according to the specific project conditions

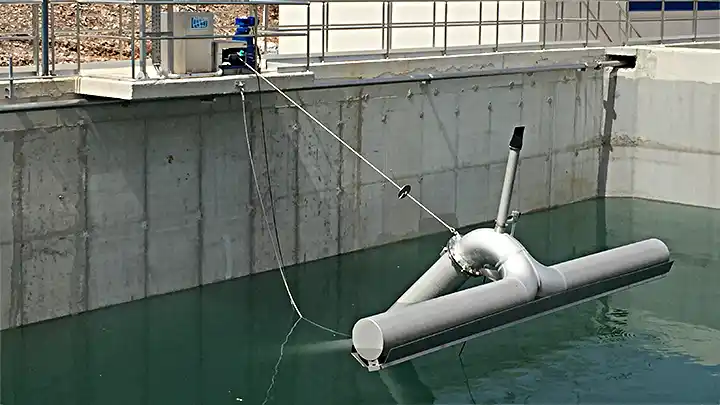

Used material AISI 304 or AISI 316 only (depending on the field of application)

Well-proven technology protected by an additional weather hood

Simple and prefabricated parts allow a quick setup

Effective barrier by baffle plate

Maintenance free and lifetime lubricated swivel joints

Clear water discharge by use of gravity

Wastewater treatment

Biogas plants

Water treatment

Municipal wastewater treatment plants/private companies:

Mobile wastewater treatment systems:

Industrial wastewater treatment systems for the food industry:

Animal breeding and slaughterhouses:

Industrial wastewater treatment plants for the non-food sector:

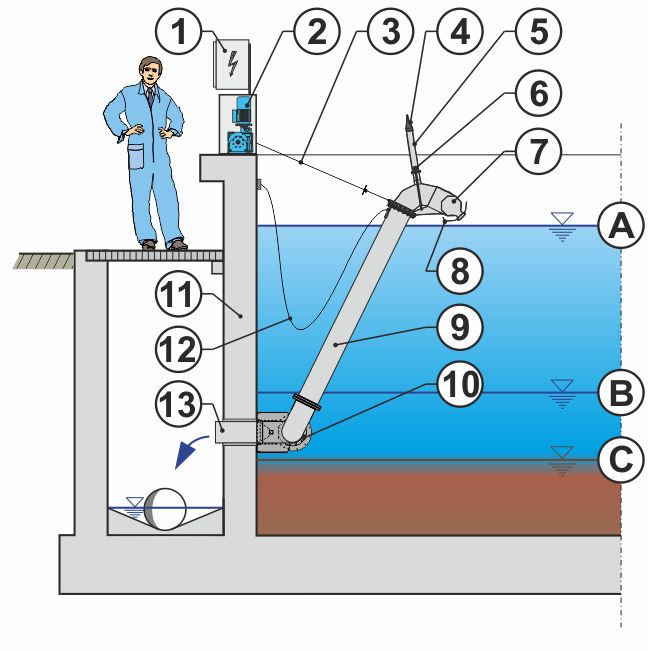

1 Local switch box or control box

2 Electrical winch

3 Lifting rope, stainless steel

4 Air vent valve

5 Air vent pipe

6 Conductive sensor (option)

7 Inlet pipe

8 Sludge baffle / barrier for floatings

9 Connection pipe

10 Swivel joint / rotating link

11 Concrete wall

12 Catching rope, stainless steel

13 Discharge of cleared wastewater

A Maximum water level

B Minimum water level’

C Sludge level

The standard BSK®-Decanter is used in 7 different sizes (pipe diameters). For normative applications (WLmax = 5.0 m, WLmin = 3.0 m, head loss = 1.0 m) the following capacities of each size apply:

| Product Type | Qab [m3/h] |

|---|---|

| BSK®-DCW 100 | 130 |

| BSK®-DCW 150 | 320 |

| BSK®-DCW 200 | 570 |

| BSK®-DCW 250 | 790 |

| BSK®-DCW 300 | 1.180 |

| BSK®-DCW 350 | 1.650 |

| BSK®-DCW 400 | 2.160 |

Fabrication in different stainless steel grades possible:

Further additional options are available.

Normally, the BSK®-DCW model is used in SB-Reactors as fully automatic discharge system.

The BSK®-DSW model is typically used is basins for sludge thickening, in which the supernatant water is mainly discharged manually.

Accordingly, every BSK®-Decanter is especially adapted to its individual application.

Our operationally safe BSK®-Decanters are used worldwide, e. g.:

Biogest International® GmbH

Abwassertechnische Systeme

Berthold-Haupt-Str. 37

01257 Dresden, Germany